In the fast-evolving industries such as mining, dredging, and construction, the demand for specialized equipment that can adapt to diverse operational needs is greater than ever. CNSME Pump distinguishes itself by offering custom sand gravel pump solutions tailored precisely to each application. Recognizing that no two projects are alike, the company’s approach focuses on developing pumps that are designed from the ground up to meet precise operational parameters, ensuring maximum efficiency, durability, and cost-effectiveness. Their customized pump designs help clients overcome unique challenges, making CNSME a leader in providing flexible, high-performance solutions worldwide.

Building for Tough Conditions with Tailored Materials

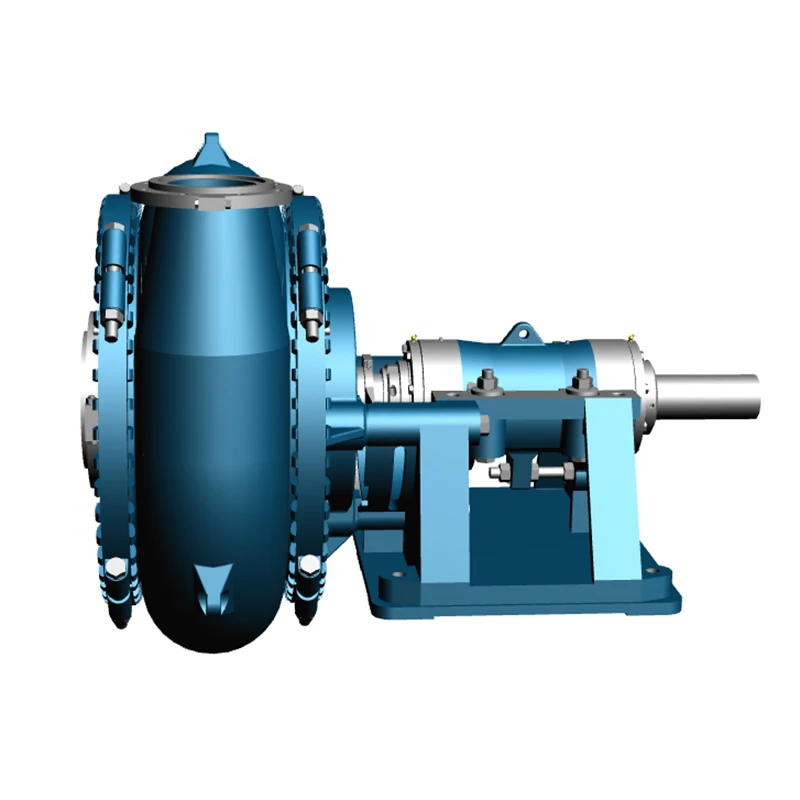

One of the key aspects of CNSME’s custom pump designs is the meticulous selection of materials tailored to the specific conditions of the application. Industries dealing with heavy abrasive materials require pumps made from high-quality wear-resistant alloys like high-chrome, rubber-lined liners, or wear plates that are selected based on the abrasive level of the slurry. CNSME works closely with clients to understand their operational environment and then recommends the best combination of materials to maximize lifespan. The use of custom alloys, combined with advanced manufacturing techniques, ensures that each pump can withstand the wear and tear associated with handling challenging materials, reducing downtime, and increasing productivity.

Perfecting Hydraulic Configuration for Optimal Performance

Hydraulic design is at the core of creating a custom sand gravel pump that fits specific operational needs. CNSME’s team of hydraulic engineers collaborates with clients to analyze flow regimes, slurry compositions, and pumping distances. This detailed assessment influences the design of impeller profiles, casing shapes, and liner configurations tailored to deliver the desired flow rate and pressure. By customizing the hydraulic setup, CNSME can develop pumps that maximize throughput while reducing energy consumption, thus offering a more sustainable and economical solution. Their ability to fine-tune hydraulic parameters makes each pump unique and better suited to its particular application, whether it’s high-volume dredging or precise slurry transfer.

Designing for Flexibility Across Applications

CNSME’s strength lies in the versatility of their custom designs, which span a broad spectrum of use cases. Whether a project involves sand extraction, gravel dredging, tailings pumping, or long-distance slurry transportation, CNSME can engineer a pump tailored to meet those specific needs. Customization extends beyond materials and hydraulic configuration; it also includes adjustable impeller sizes, inlet and outlet configurations, and optional auxiliary equipment such as agitation systems or high-pressure seals. This level of flexibility ensures that clients have a solution that seamlessly integrates into their existing operations, providing reliable performance across diverse environments and application demands.

Simplifying Maintenance with Custom Features

Heavy-duty applications often involve complex operations that, if disrupted by maintenance issues, can lead to significant delays and costs. CNSME’s custom pump designs are also focused on ease of maintenance. They incorporate features such as quick-change liners, removable wear plates, and accessible bearing assemblies, all chosen to facilitate simplified servicing. The custom configuration considers the specific operational cycle, allowing technicians to perform repairs quickly without extensive disassembly. This not only minimizes downtime but also enhances operational safety. For industries where uptime is critical, these tailored design features provide a competitive advantage, keeping workflows uninterrupted and costs under control.

Ensuring Safety and Environmental Compatibility

Incorporating safety and environmental standards into custom pump designs is a priority for CNSME. Each pump is engineered with features that maintain operator safety, such as pressure relief valves, vibration damping, and secure sealing systems that prevent slurry leakage. For environmentally sensitive applications, the company emphasizes designing pumps that operate efficiently to reduce power consumption and emissions. They also consider environmental protection by minimizing spill and leak risks, which are crucial in maintaining compliance with strict regulatory requirements. Tailoring these safety and eco-friendly features to specific project needs highlights CNSME’s commitment to responsible engineering and sustainable industry practices.

A Collaborative Approach with Clients

What sets CNSME apart as a custom pump manufacturer is their collaborative approach to design. They believe in working closely with each client from initial consultation through to final testing and commissioning. This process involves understanding the unique challenges faced by the operation, reviewing site conditions, and refining design specifications based on real-world data. CNSME’s engineers provide ongoing support during installation and commissioning, ensuring the custom pump functions precisely as intended. This partnership ethos builds long-term relationships, allowing clients to benefit from innovative solutions that are truly tailored to their operational needs, ultimately boosting efficiency and long-term success.

Leading Innovation for Future Needs

CNSME’s dedication to innovation is evident in their continuous investment in RD, enabling them to develop increasingly sophisticated custom solutions. They leverage the latest technology—such as advanced computer modeling, high-performance materials, and precision manufacturing—to push the boundaries of what custom sand gravel pumps can achieve. This forward-looking approach ensures that their clients stay ahead of industry trends, with equipment designed not just for today’s needs but also adaptable for future advancements.